India as it stands today is mostly made up of people and information, the result of generational evolution. This amazing little continent is full of history and culture. The age-old statue’s beauty is an important part of India’s past. If you visit almost any rural area of India, you will see how incredibly self-sufficient the people are, doing almost anything they need

One group of these ether artists live in the eastern Indian state of Odisha, where the country’s oldest handicrafts date back to the Indus Valley civilization It has an ancient form This fascinating art form has been practiced for thousands of years and cannot take what beautifully designed are stunning day plans and a lasting legacy.

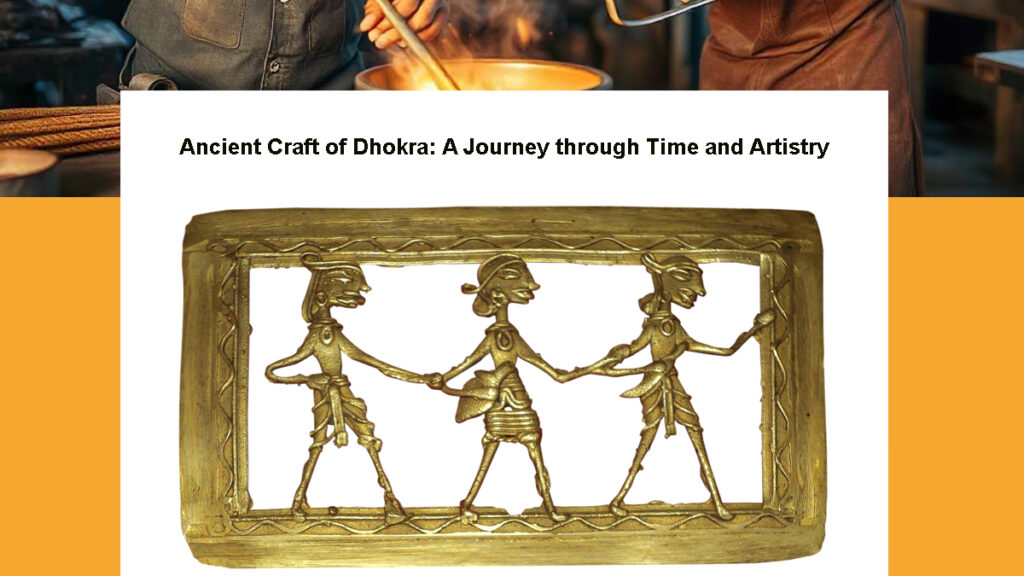

India’s cultural diversity reflects its cultural richness. The country’s traditional crafts and dances have preserved its historic artistic traditions. Dhokra art, also known as Dokra art, is such an art form. Before understanding the background and origins of this ancient metal art, it would be useful to delve into its creation.

Dhokra Art: What is it?

The craft is called cire perdue, or lost-wax casting, and it involves non-ferrous metal casting. It is estimated that this method has been around for around 4,000 years. The first known artifact made using the lost-wax technique is a statue depicting a dancing doll discovered during an excavation in Mohenjo-Daro.

What is the origin of Dhokra Art?

The Dhokra Damar tribes of West Bengal, who were the original practitioners of this art form, are the source of the term Dhokra. Later, the practice of casting dhokra extended to South, East, and Central India. Hollow casting and solid casting are the two forms of casting. While solid casting is practiced in South India, particularly Telangana, which received a GI badge for its Adilabad Dhokra skill, hollow casting is practiced in Central and Eastern regions, such as Chhattisgarh, Madhya Pradesh, Jharkhand, and West Bengal.

Since it is mostly created in the Bastar Region, the art form is also known as Bastar Art in Chhattisgarh. The Jhara and Ghadwa tribes in the state mostly perform it. The districts of Raigarh and Bastar are home to the Jhara and Ghadwa communities, respectively. An amazing range of statues are created in this art form, such as Nandis, Tribal Statues, Horses and elephants, Deer, and so on.

Bell Metal, an alloy of brass, nickel, and zinc oxide, is used to make Dhokra crafts. Despite having modest origins in clay core, these objects have become extremely popular worldwide in recent decades.

Charming Dhokra from Odisha

Although Dhokra is done in several regions of India, such as West Bengal, Chhattisgarh, and some areas of Jharkhand, Odisha is recognized as a hidden treasure for this art form. There are various tribal settlements where art thrives, each with its own distinct motif and style.

- Dhenkanal & Keonjhar: The Odishan districts of Dhenkanal & Keonjhar are well-known for their Dhokra, which is distinguished by its vivid geometric patterns and figurines that show tribal deities and ordinary life. The items have a unique appeal that comes from the bell metal utilized in them. Sadeibareni is the most well-known village in this area, and there are a few other communities where the craft is still practiced.

- Rayagada: Known for its elaborate and delicate work, Rayagada is another sanctuary for Dhokra. Here, jewelry, figurines, and home goods with flower and animal designs are expertly crafted by local artisans. The Dongria Kondh clan produces black dhokra crafts, which are highly sought after globally.

- Mayurbhanj: The district of Mayurbhanj has a thriving Dhokra tradition. The sculptures of horses and elephants made here are especially in demand because of their realistic characteristics and fine precision.

Dhokra from Odisha provides a distinctive viewpoint on this antiquated art style. Using locally obtained materials distinguishes Odisha Dhokra, the influence of tribal art styles, and the focus on usefulness. The artistic expressions and cultural traditions of the tribal groups of Odisha are embodied in these handcrafted pieces, which are more than just ornamental items. Each item you hold is a doorway into India’s ancient ways of life, not just a work of art created via years of knowledge transmitted.

The Method Used to Create Dhokra Art

Let’s examine the thirteen processes that go into making Dhokra art.

Making the Mold

- Step 1: Powdering and sieving black mud, also known as Kaali mitti, is the first stage in the construction of Dhokra metal art. This mud is then utilized to create the core clay sculpture. Usually, the female members of the home handle this task.

- Step 2: A coarse clay mixture is produced when rice husk and clay are combined and kneaded.

- Step 3: After the dirt dough is done, it is shaped into a sculpture and allowed to dry fully in the sun. This is an important stage to ensure the composite mold model holds its shape during the process and doesn’t contain any extra water. Another method for drying the model is to give it a gentle oven fire. This clay-mud model resembles the finished cast.

Getting Beeswax Strands Ready

- Stage 4: The next stage in the procedure involves using a bundle of resin or beeswax. Thin strands are removed from beeswax bundles using a device called “Pichki” that resembles a sieve and an inventive tool called Thassa. The wax bundle is used to create threads, as fine as 1 mm in diameter, which the artist uses to wrap the clay sculpture. This is the most important phase in making Dhokra art because it takes constant effort to become skilled at pulling the beeswax into thin wires and skillfully wrapping them around the mold.

Putting on the Mould Cover

- Step 5: The artist next makes a sticky solution from the leaves of green beans, often referred to as “sem,” and covers the mold with it.

- Step 6: Utilizing the strands made in Step 4, thoroughly cover the mold.

- Step 7: Using the wax bundle, additional patterns, designs, and decorations are created individually and affixed to the mold. At this point, the final design starts to take shape. Any uneven mold surfaces are smoothed off with instruments like wooden spatulas.

Getting the Outside Covering Ready

- Stage 8: The next stage involves mixing charcoal, sawdust, and clay and covering the mold with it. The ducts are designed so that the wax can drain away and the melted metal can fill in the space that the wax left behind.

- Step 9: After the mold has been sun-dried, another layer of clay is placed. After this layer dries, the mold is given a last layer of rice husk and dengur.

- Preparing the mould for baking

- Step 10: It’s time to bake the mold. The artist bakes the mold at temperatures approaching 1100 degrees Celsius. During this procedure, the wax melts away, creating a tiny space between the two clay mixture layers.

Filling the Metal Pot

- Step 11: Melt some brass metal pieces, then pour the molten metal through the ducts into the cavity. As it solidifies, the melted metal embellishes the mold’s shape and design.

- Step 12: After that, the mold is allowed to cool for at least two or three hours. Frequent misting of water facilitates faster cooling. It also softens and facilitates the mold’s breaking open.

The Complete Work Is Prepared!

- Step 13: The finished product is prepared for a final touch when the mold is smashed with a hammer. The artist enhances the final product’s attractiveness by brushing, filing, and buffing it with various tools.

To ensure that each of the 13 steps is executed with excellence, this Bell Metal art technique calls for knowledge and experience. The artist must maintain the mold’s shape until the very end of the procedure. As previously mentioned, the procedure is quite complex, time-consuming, and takes years and years of practice to become proficient at. Additionally, as each mold may only be used once, every final product is unique. Only after the artist has perfected the ability to work with clay and metal will the final creation be flawlessly created.

Not only is this metallurgical art form among the oldest, but it’s also regarded as the most sophisticated in its discipline. It makes sense that the charming beauty of these handicrafts continues to captivate us.

The Persistence of Dhokra Art

The quality of this exquisite artwork has decreased recently. The final product is pricey to draw in customers due to the continuous rise in raw material costs. Artists have so had difficulty creating their masterpieces. The decline of this artwork has also been attributed to a lack of inspiration, encouragement, and knowledge of new designs, as well as an unwillingness to adapt to modernity.

Even though there is still a significant market for these sculptures in Europe and beyond, their production is delayed in cities like Milan, Paris, and London due to outdated methods and limited access to contemporary technology.

Dhokra in contemporary times

Over time, the craftspeople have adjusted to the latest advancements in artistic mediums. These days, they produce many innovative designs that cater to the tastes of contemporary societies, including keychains, jewelry, storage units, and ornamental items.

Here are some methods to immerse yourself in Dhokra art if its allure enthralls you:

Go to Odisha

Travel to Odisha and experience the cultural center of Odisha Dhokra. See the process of manufacturing Dhokra firsthand, visit artisan villages, and engage with the craftspeople. To encourage Dhokra tourism, various government programs and non-governmental organizations host seminars and trips. Furthermore, you can purchase directly from these regional artists when you visit, supporting the continued practice of this trade. In addition, they will get paid immediately.

Examine Internet Marketplaces:

Many websites display and provide genuine Dhokra jewelry straight from the makers. Many e-commerce sites that source from traditional and modern dhokra craftspeople allow you to peruse many of these products.

Even though this craft is still practiced in some areas, we must continue its preservation. Without our help and the application of fresh design principles to the content, it cannot continue. We are always experimenting with the Dhokra technique, thus the possibilities for exploring it in new, modern formats are endless.